Top 10 Multiparameter Sonde Tips for Marine Water Quality Monitoring

Monitoring water quality in marine environments such as estuaries, harbours, and coastal reefs presents a unique set of challenges. From saltwater corrosion and tidal forces to sediment disturbance and biological growth, ensuring accurate and reliable data requires both technical expertise and experience in the field.

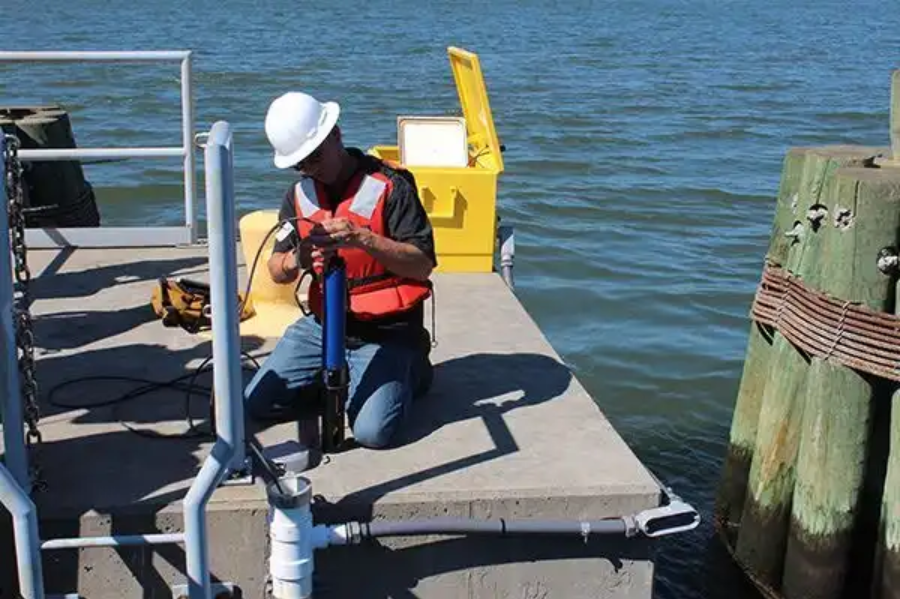

Deploying water quality instruments—such as the YSI EXO2 Sonde shown here—requires meticulous planning to ensure accurate, reliable data are collected throughout the deployment period. Photo credit: Jon Fajans

Among those who have spent years mastering these challenges is Curtis Buter, an Applications Specialist who has worked extensively with YSI’s instrumentation and sensor technologies. Across decades of field deployments, Curt has supported researchers and environmental professionals in developing robust, field-tested methods for obtaining dependable data in complex marine settings.

Drawing from his experience maintaining and testing multiparameter sondes in the Gulf of Mexico—one of the harshest aquatic environments in the world—Curt’s fieldwork has informed practical strategies that help organisations achieve success in marine water quality monitoring.

This article outlines Curt’s top ten expert tips for deploying multiparameter sondes in marine environments, focusing on effective planning, deployment strategies, anti-fouling techniques, maintenance schedules, and data validation.

1. Define Clear Monitoring Goals

Every successful deployment begins with a clear understanding of purpose. Before any equipment enters the water, it’s essential to determine what parameters need to be measured and why.

As Curt often explains, the objectives behind a monitoring programme shape every subsequent decision—from site selection and equipment configuration to maintenance intervals and data interpretation.

For instance, a project designed to establish a long-term environmental baseline will require a different setup from one investigating a pollution event or assessing regulatory compliance. Parameters such as temperature, conductivity, pH, turbidity, dissolved oxygen, and fluorescent dissolved organic matter (fDOM) are typically included when studying potential pollution sources.

By defining precise goals, environmental teams can ensure their multiparameter sondes are configured appropriately and that the data collected are meaningful, consistent, and scientifically defensible.

2. Choose a Suitable Deployment Duration

Determining how long to leave an instrument in the water is one of the most common questions in marine water quality monitoring. According to Curt, there is no one-size-fits-all answer—it depends on factors such as local biofouling rates, water temperature, power supply, and the specific sonde model in use.

Short-term sampling may capture momentary conditions but risks missing key changes caused by rainfall, tides, or algal blooms. Continuous monitoring, by contrast, provides a comprehensive record of environmental fluctuations over time.

In his experience, Curt typically leaves YSI EXO2 Sonde deployed for around five weeks before recalibration becomes necessary. He advises beginning with shorter intervals between site visits and gradually extending them as familiarity with local conditions grows.

Longer deployments demand more robust power systems, greater attention to anti-fouling measures, and thoughtful planning. Curt emphasises that careful preparation at this stage prevents costly data loss and ensures each deployment achieves its intended scientific value.

3. Select a Representative and Accessible Site

Choosing an appropriate deployment site is one of the most important steps in any monitoring project. The site must reflect the larger environment being studied, while remaining safe and practical for routine maintenance.

Curt highlights four essential criteria when evaluating a site:

- Representativeness: The site’s water characteristics should reflect the broader study area.

- Accessibility: Teams must be able to reach the location safely in varying conditions.

- Security: Equipment should be protected from tampering, vandalism, or damage by wildlife and boat traffic.

- Permission: Proper authorisation must be obtained for property access and monitoring activities.

In Curt’s fieldwork, dock- or pier-based locations often strike the best balance between accessibility and environmental representativeness. Whether near an industrial outfall or within a coastal estuary, selecting the right site ensures that collected data accurately reflect true marine conditions.

4. Select the Right Deployment Method

Selecting the right deployment method for multiparameter sondes is crucial in marine water quality monitoring, as it depends on site depth, currents, local conditions, and overall study objectives. Common deployment setups include:

- 316 stainless steel chains or PVC tubes for vertical or horizontal stabilisation

- Fixed mounts on piers, pilings, or dock structures

- Buoy-based systems for midwater or offshore monitoring locations

- Vertical profilers for collecting high-resolution depth profiles

Photo credit: Jon Fajans

With any method, consider whether you will use internal power from the sonde’s onboard batteries or external power from a larger battery housed in waterproof casing or mains supply.

Whether the sonde is suspended from a chain or positioned inside a deployment tube, it must always be installed at the same depth each time it is serviced or redeployed to maintain data consistency.

For stand-alone deployments, use a heavy-duty 316 stainless-steel chain and a carabiner. Secure deployment tubes with stainless brackets and mark their position to prevent shifting between visits.

A vertical deployment tube is generally preferred, although some shallow sites may require a more horizontal angle during low tide. When using PVC tubes, include several large holes above the sonde and smaller holes near the sensor faces to allow proper water flow and prevent stagnation. For further details, refer to the vertical tube deployment guide.

5. Implement Robust Anti-Fouling Measures

Saltwater environments promote rapid biological growth, and in marine water quality monitoring, biofouling can begin forming on multiparameter sondes within seconds. To prevent fouling and protect data quality, apply the following deterrents:

- Use copper tape on exposed sensors

- Fit copper alloy sensor guards, such as the YSI EXO2 or EXO3 Anti-Fouling Guard

- Deploy anti-fouling wipers where compatible

- Use copper mesh to deter organisms from inhabiting the sensor guard

- Apply C-spray to the instrument body (avoid sensor faces)

It’s easier to remove copper tape if sensors are first covered with a thin heat-shrink sleeve. Once the copper is depleted, simply cut along the sleeve and remove it from the sensor.

— a simple method that makes cleaning biofouling from a deployed EXO Sonde far easier.

Copper alloys are highly effective at deterring growth near sensor surfaces. The YSI EXO Sonde includes a central wiper that helps prevent fouling between samples; sondes without wipers may need more frequent maintenance.

If marine life starts nesting inside the guard, fitting copper mesh around the outside will usually discourage them.

Site visit frequency will vary depending on the local level of fouling. Watch for high-risk periods, such as warm months or seasons with elevated nutrient input. The aim of anti-fouling accessories is to keep instruments in the field for as long as possible while maintaining high data quality and reducing maintenance costs.

For further insight, see our webinar How Anti-Fouling Works, which explains fouling sources, impacts on data, and effective prevention methods for marine water quality monitoring systems.

6. Conduct Thorough Pre-Deployment QA/QC

Before any fieldwork begins, thorough preparation ensures that multiparameter sondes deliver accurate results throughout the deployment period. In marine water quality monitoring, proper pre-deployment QA/QC (quality assurance and quality control) helps identify potential issues before they compromise your data.

Before heading to the field:

- Calibrate each sensor with the correct standards

- Record baseline readings in those standards

- Confirm communication with your laptop, handheld, or data logger

- Log serial numbers and equipment configuration

- Check all batteries with a voltmeter to ensure proper voltage

Always follow standard operating procedures and good laboratory practices for calibration. Remember that most temperature sensors cannot be calibrated; they must be verified within specification before adjusting other parameters.

After calibration, it’s advisable to run the instrument in an aerated bath overnight, or at least for a few hours, to confirm stability and data reliability. Never assume new batteries are fully charged—verify voltage before deployment. A pre-deployment checklist can prevent avoidable problems and ensure the success of your marine water quality monitoring project.

7. Maintain a Regular Field Schedule

Consistent maintenance is key to keeping multiparameter sondes performing accurately in challenging marine water quality monitoring environments. Even with anti-fouling systems in place, marine growth and sediment accumulation are inevitable, so routine site visits are essential.

During each site visit:

- Clean the sonde and sensors (refer to the manufacturer’s cleaning guide)

- Remove any biofouling from the deployment tube

- Clean solar panels if using an external power source; apply a light coat of C-spray to help rain remove debris

- Check for physical damage to cables and fittings

- Replace or recharge batteries as required

- Recalibrate sensors or swap with a pre-calibrated sonde

Always document every maintenance visit for quality assurance. Take clear photos of the sonde, sensors, and site conditions. Visual records are invaluable when explaining anomalies or data trends later on.

— making regular site visits and equipment maintenance essential for reliable performance.

Don’t overlook the deployment site itself. Check that holes in the deployment tube remain clear and that the solar panel, brackets, and housings are in good condition. Regular upkeep of both the equipment and site helps maintain data quality, extend deployment duration, and reduce long-term costs.

If maintaining remote or complex installations is challenging, professional support services can help manage maintenance schedules and ensure continuous, reliable data from your marine water quality monitoring system.

8. Perform Post-Deployment Quality Checks

When a deployment period ends, immediate post-deployment QA/QC is essential to verify data accuracy and instrument performance. For marine water quality monitoring, this step helps determine whether fouling or drift has affected measurements and ensures data integrity before redeploying your multiparameter sondes.

Upon retrieval:

- Take photographs of the site and equipment before disturbing the sonde

- Inspect the instrument for fouling, corrosion, or physical damage

- Without cleaning the sensors, take side-by-side readings using another calibrated sonde or handheld meter

- Test the deployed sonde in standards to identify any drift or fouling interference

- Recalibrate the sensors or swap the sonde for a freshly calibrated one

- Review deployment data for gaps, spikes, or inconsistencies

Shown here, a YSI EMM700 Buoy is deployed in coastal waters for marine water quality monitoring.

Photographs can often explain unusual readings, such as data spikes caused by biofouling or mechanical interference. Taking these side-by-side measurements also helps confirm if readings remained within specifications during the deployment period.

After initial testing, gently clean the sonde housing and sensor faces, then verify readings again in calibration standards. If the instrument still shows drift, it could indicate either severe biofouling or sensor ageing. Following this process ensures that data from marine water quality monitoring programmes remain reliable, defensible, and traceable over time.

9. Care for and Store Equipment Properly

Proper post-deployment care is vital for extending the life of multiparameter sondes and ensuring accuracy during future marine water quality monitoring campaigns. Saltwater exposure, humidity, and poor storage practices can quickly damage delicate sensors and connectors if not managed correctly.

After retrieval:

- Rinse all sonde components thoroughly with freshwater

- Clean and inspect connectors, applying a thin layer of silicone grease to prevent corrosion

- Dry the instrument completely before storage

- Remove or recharge batteries to prevent leakage

- Inspect cables, seals, and O-rings for wear or damage

For YSI EXO sondes, ensure wet-mate connectors are thoroughly cleaned and lubricated until they shine. Rinsing and drying the sonde properly before storage helps prevent microbial growth or corrosion from residual seawater.

Never store an instrument with batteries installed. Instead, remove them and use a new set before redeployment to prevent voltage loss and ensure a consistent power supply.

This is also an ideal time to check cables, seals, and handheld devices for integrity before the next deployment cycle. Proper cleaning and storage protect your investment, ensuring your multiparameter sondes remain dependable for long-term marine water quality monitoring.

10. Document Every Detail

Thorough documentation is one of the most important aspects of any marine water quality monitoring project. Accurate records ensure data traceability, help identify trends, and provide evidence of correct procedures should your results ever be questioned. For users of multiparameter sondes, careful documentation also aids in troubleshooting and future maintenance planning.

Always record key details such as:

- Site coordinates and a brief site description

- Deployment method, depth, and duration

- Calibration values, standards used, and sensor configuration

- Maintenance notes, inspection findings, and photos

- Any unusual environmental observations or anomalies

Good documentation not only helps with data interpretation but also supports regulatory compliance and quality assurance. Field notes, metadata, and photographs are invaluable when explaining data variations or reviewing long-term trends. In scientific monitoring, a well-documented process is as critical as the data itself.

Creating a consistent logging procedure ensures that all deployments of multiparameter sondes follow the same quality standards, improving reproducibility and reliability across future marine water quality monitoring programmes.

Curtis Buter’s Legacy of Field Expertise

Deploying multiparameter sondes in marine environments demands careful preparation, technical understanding, and attention to detail. From selecting the right site and deployment method to preventing biofouling and maintaining calibration, each step plays a vital role in ensuring accurate and defensible data.

Reliable marine water quality monitoring depends not only on robust equipment but also on good field practice. Following these best practices—defining clear goals, using consistent methods, and maintaining detailed records—will help achieve high-quality, long-term environmental data.

At Lab Unlimited, we are a trusted distributor of high-quality multiparameter sondes and marine water quality monitoring instruments. Our experienced team can help you choose the right equipment, anti-fouling accessories, and calibration solutions to ensure accurate, long-term performance in any marine environment. If you’d like expert advice or more information about our product range and deployment support, contact us today — we’re here to help you achieve reliable data and successful monitoring results.

|

To find out more: |