New Standards in Sustainable Refrigerated Circulators in All Performance Classes

JULABO has recently designed a range of new refrigerated circulators that are both environmentally friendly and energy efficient in light of the recent surge in environmental protection. These units cover a performance range from 200 watts to 2.5 kW. The powerful refrigerated circulators, available under the product brands CORIO, DYNEO, and MAGIO, have been essential tools in laboratories and industrial applications worldwide for many years. The latest models feature innovative technology, operating with natural refrigerants to make a substantial impact on climate protection with the aim of establishing sustainable, eco-friendly refrigerators. The larger cooling units, starting at 800 watts of cooling capacity, offer impressive energy savings of up to 70%. This is achieved using electronic expansion valves, speed-controlled compressors, and fans that adjust power consumption based on usage. These energy-efficient features result in substantial operational cost reductions in various application scenarios, leading to a quicker return on investment. Despite their high performance, JULABO's newest generation of refrigerated circulators are constructed to be remarkably compact, making them space-efficient in laboratory settings.

Which JULABO products are new?

The JULABO MAGIO MX-1800F and MAGIO MX-2500F are the latest flagship models in the sustainable refrigerated circulator lineup. These units feature a robust cooling capacity of 1.87 and 2.57 kW at 20 °C, with a wide working temperature range of -50 to +200 °C. JULABO has also introduced the water-cooled version of these powerful cooling machines, known as the 1200FW, for the CORIO, DYNEO, and MAGIO product brands.

View Now:

Additionally, the new models of reliable refrigerated circulators DYNEO DD-200F, CORIO CP-200F, and CORIO CD-200F are now equipped with natural refrigerants to incorporate eco-friendly operations. These entry-level circulators offer a cooling capacity of 0.2 kW at 20 °C in a compact design.

Lowering Environmental footprint and Operating costs

Refrigerated circulators play a crucial role in providing reliable and precise temperature control for various applications, including handling samples, test specimens, and processes in areas such as basic research, material testing, and technical systems. In many instances, partial load operation is adequate for effectively removing heat. By utilising energy-efficient refrigerated circulators, users can not only achieve cost reduction and efficiency but also lessen their environmental footprint. When considering the purchase of new laboratory equipment, it is essential to thoroughly assess the anticipated operating conditions for the intended systems to accurately gauge the potential energy savings that can be achieved.

What is energy efficiency?

Energy efficiency refers to the ability of a product to achieve a specific goal, such as precise temperature control, using the least amount of energy possible. In the context of our discussion, energy-efficient products are utilised to maintain accurate temperature control in applications while minimising energy consumption. The higher the level of performance achieved with minimal energy input, the more energy-efficient a product is considered to be. When comparing products with similar functions and performance on the market, energy efficiency serves as a benchmark for evaluating their effectiveness in achieving desired outcomes with reduced energy usage.

When can it be useful to make use of energy-efficient systems?

In the realm of temperature control systems, there is a clear differentiation between the base load and usage-dependent energy consumption. The base load represents the essential energy required to run the system, while usage-dependent consumption is influenced by factors specific to the application, such as cooling capacity needs, ambient conditions, and the type and quantity of connected devices. The level of usage-dependent consumption plays a essential role in enhancing overall energy efficiency.

To determine the potential savings, it is important to consider the specific intended use of the systems. In many common applications in laboratory or industrial settings, a fixed setpoint value is established at the start of the temperature control process. The temperature control device then works to achieve this setpoint as quickly as possible, operating all components at high load. Once the setpoint is reached, the system typically maintains the desired temperature, requiring components such as fans or compressors to operate at partial load. In these scenarios, energy-efficient temperature control systems have the potential to achieve energy savings of up to a staggering 70%.

Traditional refrigerated circulators with a cooling capacity below 500 watts typically utilise capillary tube systems. These systems are known for their energy efficiency, as they have a low absolute cooling capacity. Employing costly components such as electronic expansion valves and speed-controlled fans or compressors to enhance energy efficiency would substantially increase the cost of these systems. However, the overall impact in terms of energy savings would be minimal given their low cooling capacity.

Historically, JULABO has frequently incorporated electronic expansion valves in refrigerated circulators with a cooling capacity of 600 watts or higher to achieve energy efficiency, among other benefits. The most recent iteration of refrigerated circulators now includes speed-controlled compressors and fans to further enhance potential energy savings and cost reductions. With the introduction of the 800F and 1200F models, these new refrigerated circulators represent the first systems in their power range to leverage this energy-saving capability on the market, where both ecological footprint and cost savings are achieved.

How much energy can be saved: calculation example?

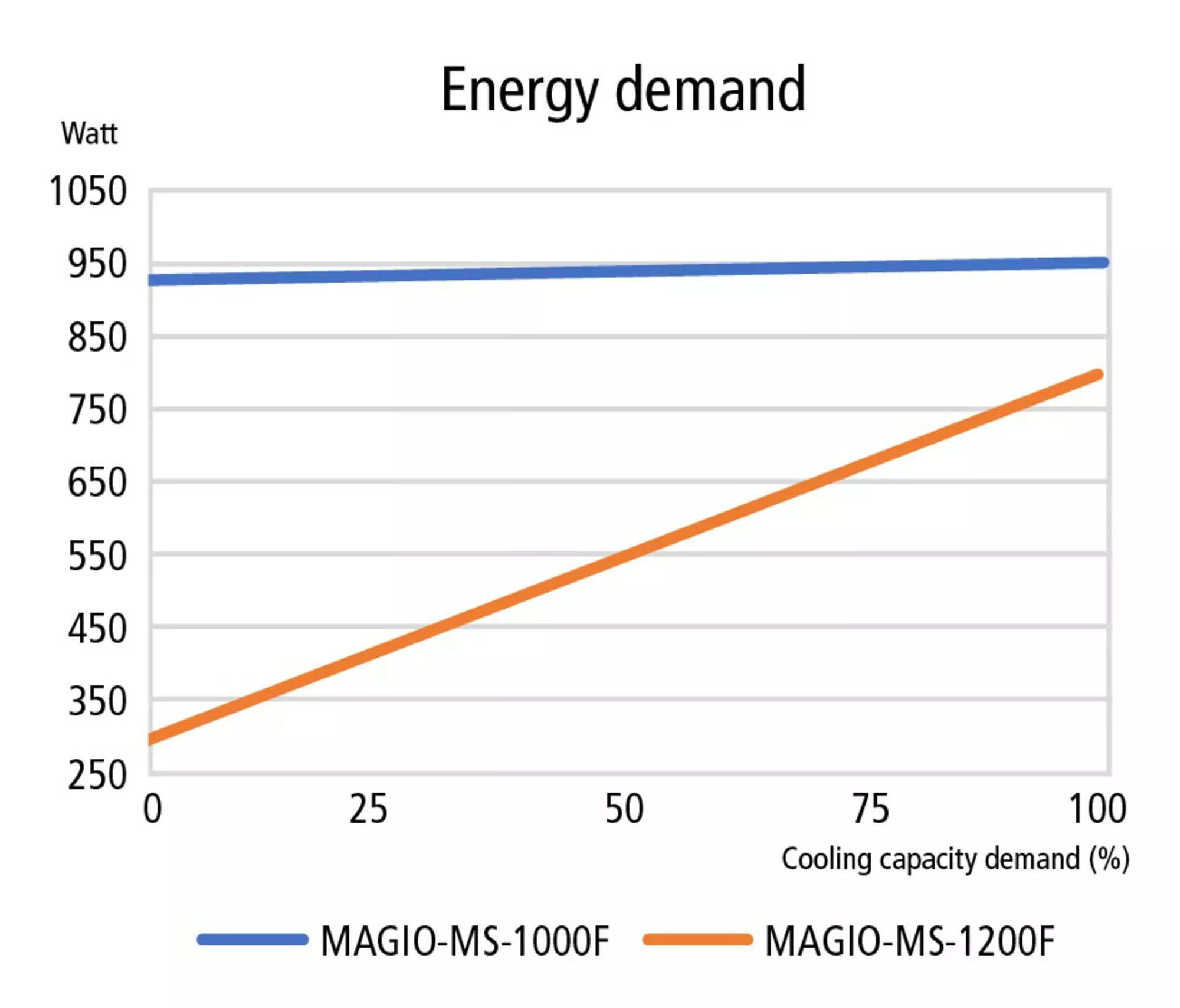

In this instance, we will be contrasting the MAGIO MS-1200F and the MAGIO MS-1000F. The MAGIO MS-1000F features an electronic expansion valve, while the MAGIO MS-1200F is equipped with a speed-controlled fan and compressor.

Operating point A:The refrigerated circulator maintains the bath temperature as specified in the table and also consumes energy to operate the pump. When there is no additional load on the cooling machine and the temperature needs to be maintained, the MAGIO MS-1200F consumes approximately 600 watts less energy compared to the MAGIO MS-1000F. This is due to the MAGIO MS-1200F having a lower proportion, as it further decreases the minimum cooling capacity and reduces the heating capacity needed for temperature control. |

|

||||||||||||||||||||||||||||||||

Operating point B:Energy savings are influenced by the cooling capacity demand. Higher potential savings are expected with lower average cooling capacity demands. Typically, refrigerated circulators do not operate continuously at 100% cooling capacity, resulting in cost savings ranging from 40-60%. Consequently, even if the cooling machine runs continuously at full power, energy consumption can be reduced by up to 150 watts, further stamping an eco-friendly footprint. |

|

||||||||||||||||||

In summary, energy savings are influenced by the cooling capacity required. Higher energy savings are achievable with lower average cooling capacity demands. As refrigerated circulators typically do not operate continuously at maximum capacity, typical savings range from 40% to 60%.

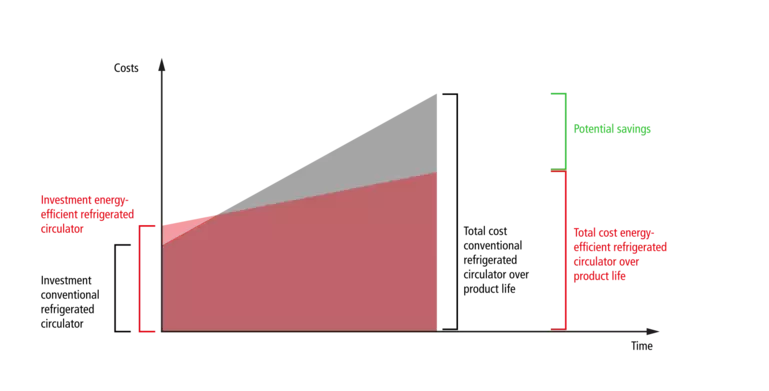

Amortization time

Refrigerated circulators with a cooling capacity of 800 watts or higher lead to significant energy savings, allowing for a quick return on the initial investment. These cost savings are a result of reduced energy consumption and specific electricity rates. To illustrate this, we will once again compare the MAGIO MS-1200F and the MAGIO MS-1000F in our example calculation. In this scenario, we consider varying temperature ramps and load requirements, with the partial load averaging around 50%. Based on this example, the energy savings would equate to 400 watts per hour. Given the global usage of refrigerated circulators, different electricity prices are considered, as the duration of use varies widely. Therefore, multiple example calculations have been provided to demonstrate the potential savings.

| Example 1 | Example 2 | Example 3 | Example 4 | Example 5 | Example 6 | |

| Typical energy savings | 400 W | |||||

| Individual electricity price | €0,10 / kWh | €0,20 / kWh | €0,30 /kWh | |||

| Individual duration of use per day, 260 days per year |

7h | 24h | 7h | 24h | 7h | 24h |

| Cost savings per year | €73 | €250 | €146 | €499 | €218 | €749 |

The provided calculation demonstrates how energy-efficient technology can lead to substantial energy savings and decreased operating expenses. Despite having low electricity costs, these systems typically achieve a payback period of less than 2 years in numerous scenarios. Additionally, the reduced energy consumption not only results in cost savings but also contributes positively towards a sustainable environment with a low carbon footprint.

Conclusion

The energy-efficient temperature control technology is ideal for numerous applications, particularly those requiring a cooling capacity exceeding 800 watts. The initial higher procurement costs are typically recovered in less than 2 years thanks to reduced electricity expenses allowing users to reduce costs and achieve return on investment. Additionally, users can contribute to environmental sustainability by utilising energy-efficient refrigerated circulators. The acquisition of JULABO refrigerated circulators represents the introduction of new standards that are in place for manufacturers to lower their environmental footprint and this can be achieved in tandem with making a return on investment.

For more information on sustainable laboratory equipment and to view a range of environmentally friendly refrigerated circulators, visit our website for diverse options that meet the latest standards in energy efficiency and environmental protection.

|

To find out more: |